Application scope:Food industry, mining equipment, sewage treatment, battery materials, energy and environmental protection, non-metallic minerals, waste sorting, pharmaceutical industry, etc

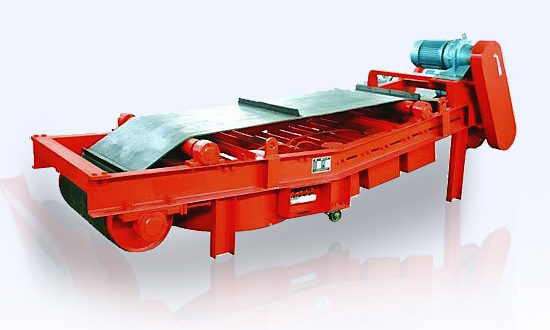

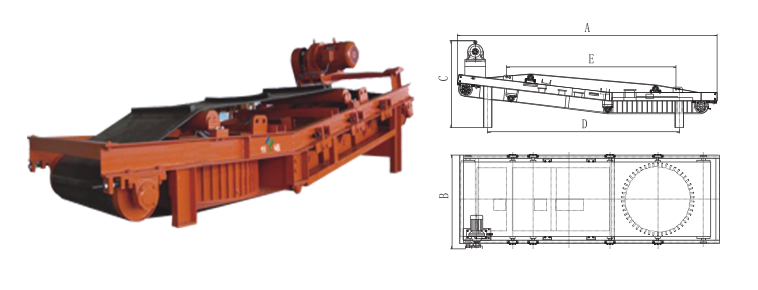

The LJK iron removal system is mainly suitable for removing iron from magnetic ore conveyor belts such as raw ore, sintered ore, pellet ore, and block ore. The LJK iron removal system relies on its unique magnetic circuit design to separate the selected materials multiple times, thereby separating the iron parts that cause damage to the production line from a large amount of strong magnetic materials with less ore content, achieving the goal of protecting the belt from scratches and protecting the subsequent crushing equipment.

Adopting discontinuous excitation, low energy consumption, stable and reliable performance.

The sorting zone has multiple composite magnetic systems, and the anti magnetic zone ensures the minimum amount of ore material carried out during iron removal.

Continuous real-time monitoring of iron removal without any iron leakage.

◇ It can effectively utilize the upper space of the belt, has strong adaptability to installation sites, and occupies less land.

◇ Less supporting auxiliary equipment, more conducive to operation and maintenance.

Address:Lebushan Industrial Park, Weicheng District, Weifang City, Shandong Province

Address:Lebushan Industrial Park, Weicheng District, Weifang City, Shandong Province

Mobile:+8618553633270

Mobile:+8618553633270

Tel:0536-8339337

Tel:0536-8339337

Email:sdhcjx1@gmail.com

Email:sdhcjx1@gmail.com

WhatsApp:+8613963654232

WhatsApp:+8613963654232