Application scope:Food industry, mining equipment, sewage treatment, battery materials, energy and environmental protection, non-metallic minerals, waste sorting, pharmaceutical industry, etc

The physical basis of the HECS eddy current metal sorting machine is based on two important physical phenomena: a time-varying alternating magnetic field always accompanies an alternating electric field; A current carrying conductor generates a magnetic field. Therefore, if a conductor is exposed to an alternating magnetic field or an alternating magnetic field formed by the rotation of a fixed magnetic field, eddy currents perpendicular to the magnetic flux of the alternating magnetic field will be generated inside the conductor. On the other hand, the mirror magnetic field caused by eddy currents in conductors, which is opposite to the induced magnetic field, generates a repulsive force on the conductor. Copper, aluminum, and other materials will leap forward along their transport direction due to the repulsive force of the magnetic field, achieving separation from other non-metallic substances and achieving the purpose of sorting. The main distinguishing criterion is the ratio of material conductivity to density, with materials with higher ratio values being easier to separate than those with lower ratio values. Separate the conductor from the material.

Scope of Application

The HECS eddy current metal sorting machine is mainly used to recover various non-ferrous metals such as copper and aluminum from household waste, industrial waste, electronic waste treatment, glass shards, waste plastic doors and windows, boiler bottom ash, and waste car slices. It can be widely used in environmental protection fields such as waste disposal, waste electrical appliance recycling, and material processing industries in the non-ferrous metal processing industry. Specifically, it mainly refers to the following aspects: ◇ Electronic waste disposal (refrigerator dismantling line); ◇ Separate aluminum cans from iron metal; ◇ Separate non-ferrous metals from boiler bottom ash; ◇ Sort aluminum or copper blocks from scrap car slices; ◇ Separate non-ferrous metals from glass shards; Separate non-ferrous metal impurities in some production lines (such as plastic recycling production lines); ◇ Separate non-ferrous metals from plastic door and window recycling; ◇ Separate non-ferrous metals from wood;

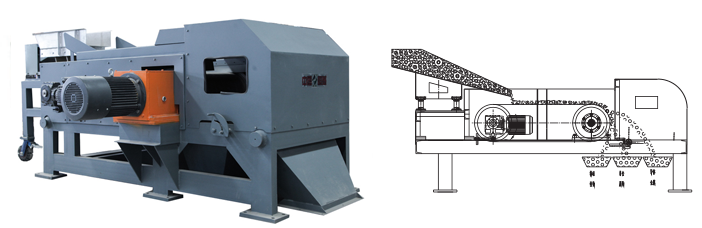

The HECS eddy current metal sorting machine consists of two parts: the main body of the sorting machine and the control cabinet; The main body mainly consists of the selection assembly, drive motor, frame, and cover. The sorting assembly is the core component of the equipment, consisting of a permanent magnet drum, a material conveying system (including a material conveyor belt, a conveyor belt driven drum, and a reduction motor).

5、 Characteristics

The HECS eddy current metal sorting machine adopts a magnetic system with NN and SS arranged alternately, and uses high-performance neodymium iron boron as the magnetic material, which makes the magnetic field strength higher, the action gradient larger, and the sorting effect better.

The speed of the magnetic roller and the belt speed of the sorting belt can be adjusted by the variable frequency speed control device and the position of the sorting plate according to factors such as the volume and conductivity of the selected material, achieving better sorting results.

This device has the advantages of simple operation, high degree of automation, and is equipped with fault alarm, fault indication, and fault start stop functions, which can provide timely protection and maintenance for the equipment.

Address:Lebushan Industrial Park, Weicheng District, Weifang City, Shandong Province

Address:Lebushan Industrial Park, Weicheng District, Weifang City, Shandong Province

Mobile:+8618553633270

Mobile:+8618553633270

Tel:0536-8339337

Tel:0536-8339337

Email:sdhcjx1@gmail.com

Email:sdhcjx1@gmail.com

WhatsApp:+8613963654232

WhatsApp:+8613963654232