Application scope:Food industry, mining equipment, sewage treatment, battery materials, energy and environmental protection, non-metallic minerals, waste sorting, pharmaceutical industry, etc

1、 Explanation

The HECP eddy current metal sorting machine can be widely used in various environmental protection fields and material processing in the non-ferrous metal processing industry. Its typical application is significant in the recovery of various non-ferrous metals such as copper and aluminum in the following industries: ◇ Separation of granular and powdery non-ferrous metals in white household wires; ◇ Sort granular and powdery non-ferrous metals from scrap steel slices; Separate powdered non-ferrous metals from the plastic recycling production line; ◇ Separate granular non-ferrous metals from plastic door and window recycling; ◇ Separate granular and powdery non-ferrous metals from glass shards; ◇ Separate granular and powdery non-ferrous metals from boiler bottom ash; ◇ Separate granular and powdery non-ferrous metals from wood recycling;

2、 Technical features

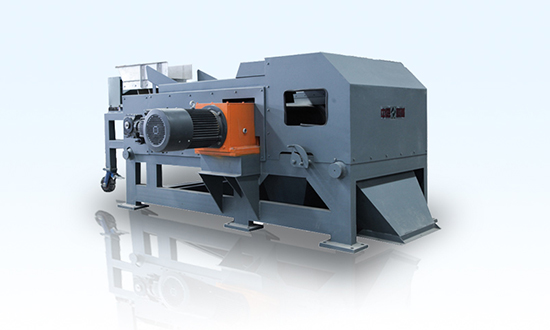

This machine is specifically designed for lightweight and small surface area granular and powdery metals, with better sorting efficiency than the HECS type.

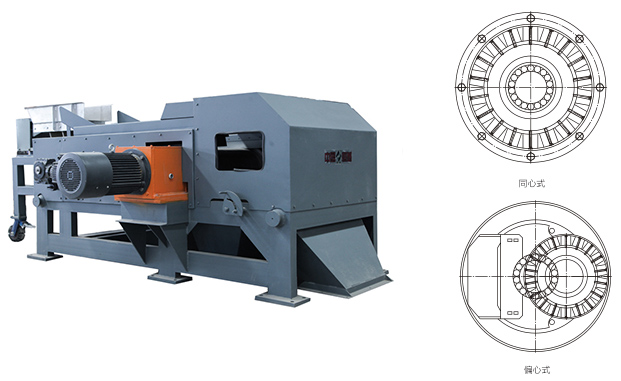

Due to the use of adjustable eccentric magnetic pole technology, it is the choice for separating granular and powdery metals. Eccentric magnetic pole technology ensures that eddy currents are concentrated in the area where materials are subjected to concentrated forces. The magnetic poles can be adjusted as needed to ensure more accurate separation points and parabolic trajectories.

The traditional concentric magnetic pole technology causes premature eddy current action time and distance, resulting in premature starting point of particle and powder metal bouncing. The parabolic trajectory of particle and powder metal is weakened under material compression, making it difficult to effectively sort. In contrast, eccentric magnetic pole technology maximizes the concentration of eddy current effects at the metal and material separation points, resulting in higher metal sorting rates and higher metal purity. Adopting an intelligent control system, the operation is smoother and more reliable, and the operation is simpler. The bearing adopts unique patented cooling technology, which ensures more stable operation and longer service life.

The magnetic poles are precision machined using CNC equipment and protected by special processes, making them more energy-efficient and environmentally friendly.

The speed of the magnetic roller and the belt speed of the sorting belt can be adjusted by the variable frequency speed control device and the position adjustment of the sorting plate according to factors such as the volume and conductivity of the selected material, achieving better sorting results.

3、 Main technical parameters

4、 Product shooting

Address:Lebushan Industrial Park, Weicheng District, Weifang City, Shandong Province

Address:Lebushan Industrial Park, Weicheng District, Weifang City, Shandong Province

Mobile:+8618553633270

Mobile:+8618553633270

Tel:0536-8339337

Tel:0536-8339337

Email:sdhcjx1@gmail.com

Email:sdhcjx1@gmail.com

WhatsApp:+8613963654232

WhatsApp:+8613963654232